INJECTION MOLD CREATION

Custom injection mold creation for a wide variety of uses and commercial sectors - nationwide distribution.

We create custom

polymer injection molds

Manufacturing in-house

at 50,000 sq. ft. facility

Products range from

marketing to fabrication

OUR PROMISE

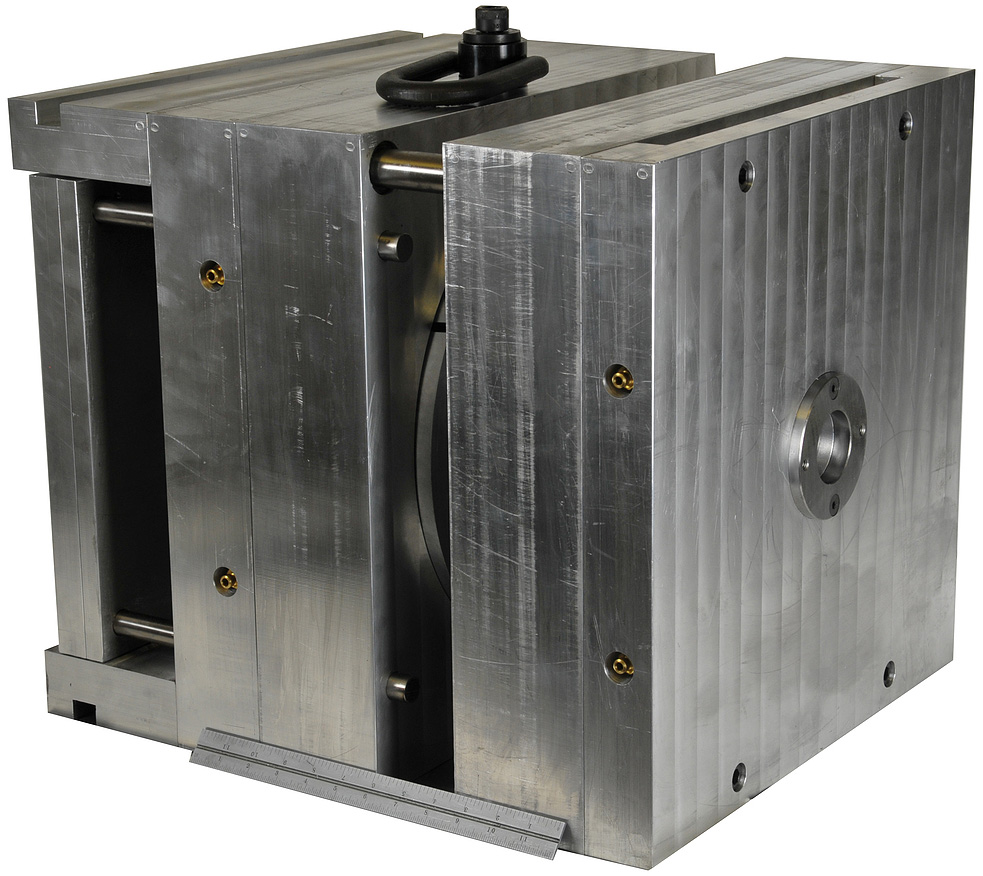

Durable injection molds built to last

Polymer injection molds are made from durable metals such as hardened or pre-hardened steel, aluminum, and/or copper alloy. There are different trade-offs as to which material you select - e.g. aluminum is typically less expensive, while steel are designed to process millions of parts during their lifetime. Copper is usually used as part of an insert to reduce cycle time and improve the look of the end product. We aim to deliver a top quality custom inject mold at reasonable rates.

Want to learn more about the innovative process of injection mold creation? Here we outline the main process.

How are molds made?

Plastic injection molds are made two ways: standard machining and electrical discharge machining (EDM). CNC is a more advanced version of the traditional standard machining, to allow for advanced precision through the use of computers. The mold design and manufacturing is highly automated, with the dimensions defined in specialized software programs. With CNC machining, you can create complex and accurate molds with the use of standard machining methods.

The EDM method is also becoming increasingly popular in the plastics industry. This method can create shapes not possible with the conventional CNC machining. As well, it also allows for pre-hardened molds to be shaped, eliminating the need for additional heat-training.

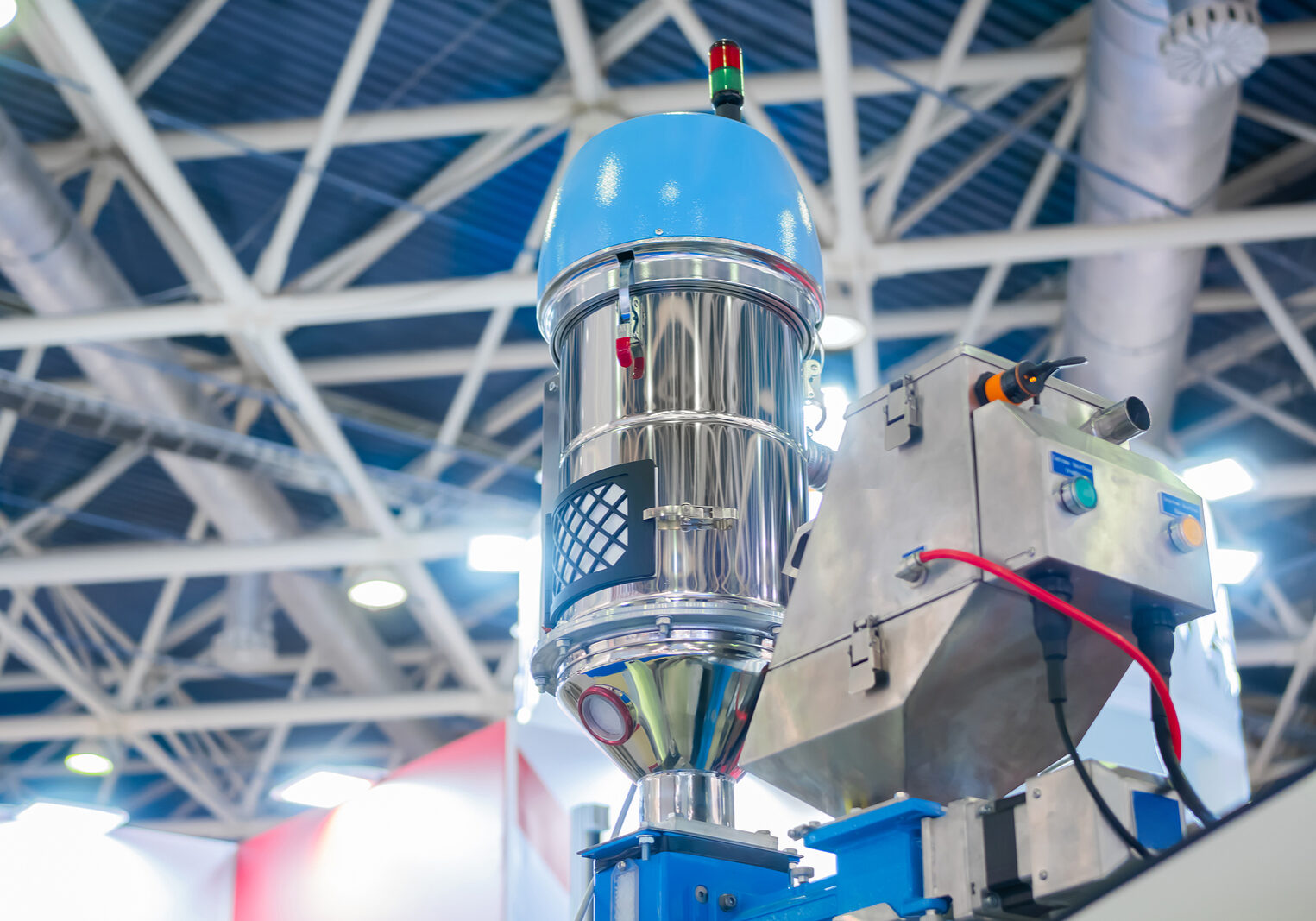

SUPERIOR QUALITY MANUFACTURING

Why choose Manufacturing Polymer Products Inc.?

Our goal is to provide excellent service, affordable rates, and top quality product. We keep up to date with new processes and technologies, to maximize efficiency in manufacturing and reduce our environmental impact. This begins in our new 50,000 square foot manufacturing facility in Dalton, GA. Here we can create completely custom injection molds across a wide variety of sectors.

As well, we are a proud member of the Society of Plastics Engineers (SPE). This is not only stay up to date on industry developments and connect with industry partners, but also to join the transition to recycled plastics and sustainable products. Consumers and companies are increasingly demanding products that reduce their environmental footprint - we're here to help.

Would you like to learn more about our injection mold creations?

Get a quote

Please fill out the form to the right, or call us today at (706) 847-1731 for more information on your specific needs. Our goal is to provide top quality products and services at affordable rates.

We can make almost anything!